But what exactly is chilled logistics, why is it so vital, and how can you find the best provider? Let’s get into it.

Chilled logistics refers to the storage, transportation, and handling of products that have to be kept at a certain temperature to maintain quality, and, in some cases, safety. Common examples of goods that require chilled logistics include:

- Fresh produce, such as dairy, meat, and seafood

- Pharmaceuticals and vaccines

- Cosmetics and chemicals

- Beverages and perishable items.

Chilled logistics is more than just refrigeration. It requires the maintenance of a temperature-controlled environment from start to finish of the supply chain process. This is known as the cold chain, and is non-negotiable for many industries.

Working with a chilled logistics, chiller hire, and cold storage rental company, you can ensure that your cooling needs are covered, allowing your operations to continue while you focus on your core competencies.

For food and pharmaceuticals, even brief exposure to unsuitable temperatures can result in spoilage or contamination. Reliable chilled logistics ensures products reach consumers in perfect condition, safeguarding health and brand reputation and significantly reducing waste from spoiled goods. In some scenarios, like pharmaceuticals, public health can be put at risk if temperature control isn’t prioritised.

In some industries, chilled logistics isn’t just a nice-to-have; it’s a regulatory must, and failing to keep goods at certain temperatures can result in legal non-compliance. Cooling solutions such as chiller hire and temporary cold storage ensure that industries stay compliant.

Customers expect consistency and quality control. A single delivery of spoiled goods can damage consumer trust, especially in industries that sell direct-to-consumer, such as food and beverages.

Reliable chiller logistics, chiller hire, and temporary cold storage systems ensure you meet consumer expectations every time.

Product loss due to fluctuations in temperature can be very costly to your business. By investing in reliable chilled logistics, companies can reduce waste, minimise insurance claims, and ensure that every product is able to be sent out to consumers or clients.

Warehouses and distribution hubs need specialised cold storage facilities equipped with backup power and 24/7 cooling to ensure consistent temperature control. Outsourcing cold storage to a trusted provider is often the most effective way to ensure consistent cooling – it’s often most cost-effective, too.

While cold storage systems can keep produce and chemicals cool while they’re stationary, getting them from A to B is the next challenge. Chilled transportation, such as vehicles fitted with high-quality refrigeration units, which keep the temperature stable over long distances. Modern vehicles often use technology to monitor the temperature.

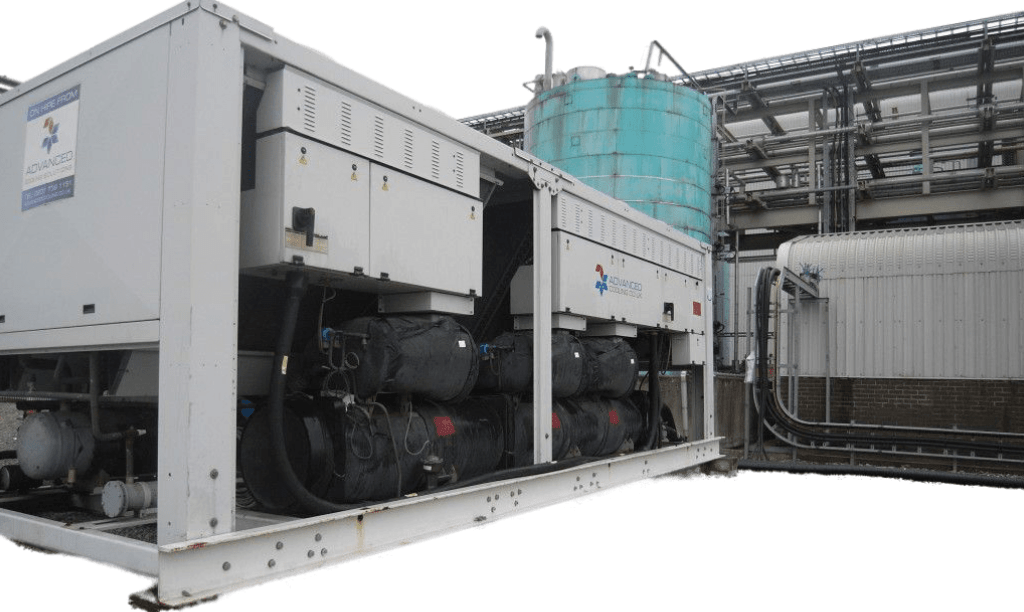

When demand surges or emergencies occur, chiller hire can step in to save the day, especially from a reliable provider like Advanced Cooling. Chillers are used in environments where temperature control is non-negotiable, and renting chillers rather than buying them outright can be much more cost-effective and practical for businesses.

Even the best technology is only as good as the people running it. In order to ensure chilled logistics runs smoothly, you’ll need trained staff who can ensure equipment is used correctly and processes are followed by the book. If you don’t have an on-site staff member for this, outsourcing your chilled logistics needs is the answer.

The importance of chilled logistics applies especially to some industries.

At Advanced Cooling, we support cold chains in modern supply chains by providing temporary cold storage as well as chiller hire to plug the gaps in cooling systems.

We’ve built up a wealth of expertise thanks to our years of experience in the cooling systems sector. We work with industries from pharmaceuticals to food and beverage to ensure temperature-controlled environments for businesses that need them, resulting in reduced waste, better compliance, and better quality control.