One of the most important elements of this project would achieving good airflow around the area.

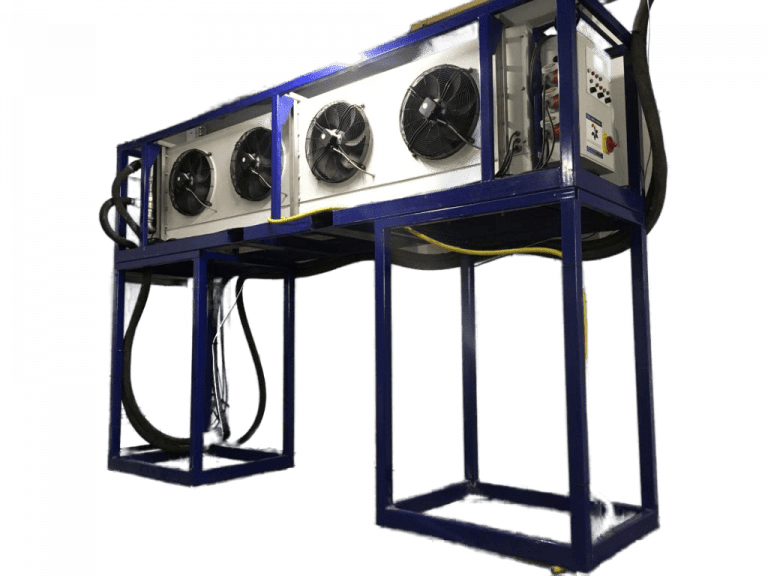

Because of this, and after a lot of head scratching, it was decided to take the difficult option and mount six units on the high level gantry. Another 12 were mounted on scaffold platforms on the rear wall of the warehouse.

The intention being to circulate the air effectively around the warehouse. Once this decision was made, careful attention was paid to the planning of this operation. Of paramount concern, was safety- when your lifting 700kg of air handling unit 17mt in the air, it needs to be safe. That’s why we enlisted the help of a professional lifting company with a telehandler.

It was tricky, but in the end all six AHU’s made it safely onto the gantry. The remaining 12 AHU’s were fitted in pairs onto scaffolding platforms at the rear of the warehouse.

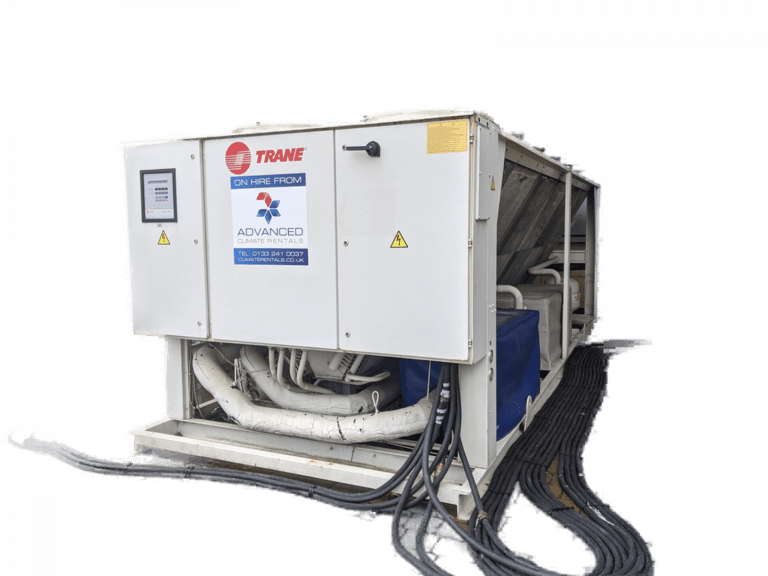

Two chilled water cooling systems were used with a total capacity of 950kw. The chillers were located externally and piped with 10 bar rubber suction hosing. For quick installation, our pipe-work systems use Camloc hose connections and branch fittings. Its a great system, and very reliable.

Heating of the air was by electric heater banks fitted to the AHU’s- 18kw’s total each.

What about control? We set-up two control zones, one for the the low level AHU’s and the other for the high level. One AHU on each zone was set-up as a master, controlling all slave unit’s heating and cooling functions.

All in All, quite a challenge to design plan and install this temperature controlled warehouse partitioning project. But thats why we do this, right?