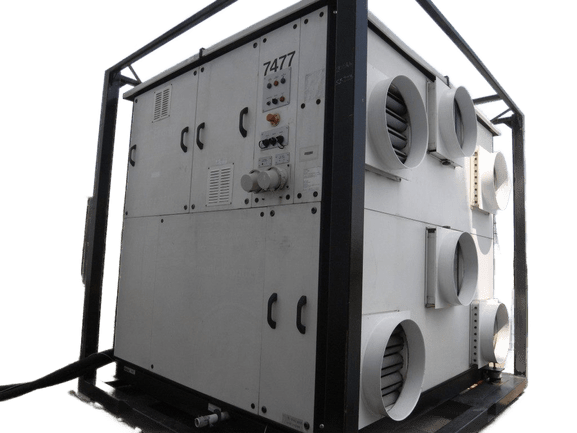

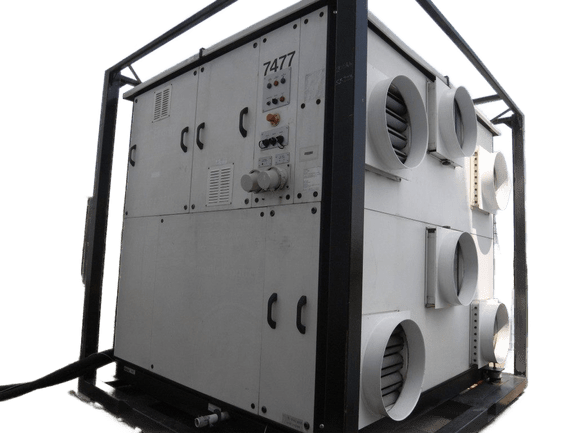

Temporary Hospital Ventilation Hire At The Rsh In Southampton

This heat exchanger skid was installed to allow the use of the sites LTHW system to heat the AHU’s Heating coil. The primary AHU circuit was charged with a glycol mixture held in capacity with a buffer tank. Temperature control was achieved by starting the primary pump from the AHU’s controller. Because this long term temporary hospital ventilation hire was being operated in the winter months, the glycol mixture protected the heater battery from frost.