This Article provides an in-depth exploration of chiller hire and how it is delivered, with the key highlights being:

🟧 Purpose: Emphasises the necessity of CH to ensure that problems with water cooling issues do not adversely affect business operations.

🟧 CH Types: It categorizes CH into three types: Full Turnkey supply and installation, planned and emergency response.

🟧 Design Considerations: Discusses various CH design strategies, which influence equipment selection and application.

🟧 Team Roles: Identifies key participants in the design and delivery process.

🟧 Benefits: Highlights advantages like maintaining cooling capacity, improving system reliability, enhancing energy efficiency, and mitigating business risks.

Procuring chiller hire services can offer several benefits:

- ✅Fast response to situations: inherent to chiller hire services is the requirement to supply equipment and services quickly to limit downtime and losses.

- ✅Ensuring futureproof solutions: It is not unusual for applications to change in nature and scope. Modular chiller hire installations lend themselves to ongoing responsive adjustments to changing needs..

- ✅Improving Reliability and Uptime: Installation of modern chiller hire equipment and systems helps to prove reliability and uptime, preventing unplanned future downtime.

- ✅Enhancing Energy Efficiency: Better outcomes are achieved when modern equipment is tailored to specific needs saving costly energy.

- ✅Testing New Processes: Chiller hire can be very useful for testing new processes with uncertain or changing needs, and a very useful stepping stone to specifying a final design.

- ✅Mitigating Business Risks: Conducting a prompt chiller hire installation helps mitigate business risk for the operators and owners by resolving quickly issues that cause delays, service disruptions, and costly downtime.

In very general terms these are the three main response scenarios

- Full turnkey ensures fast outcomes.

- Planned- including contingency

- Emergency

🟧 Full Turnkey

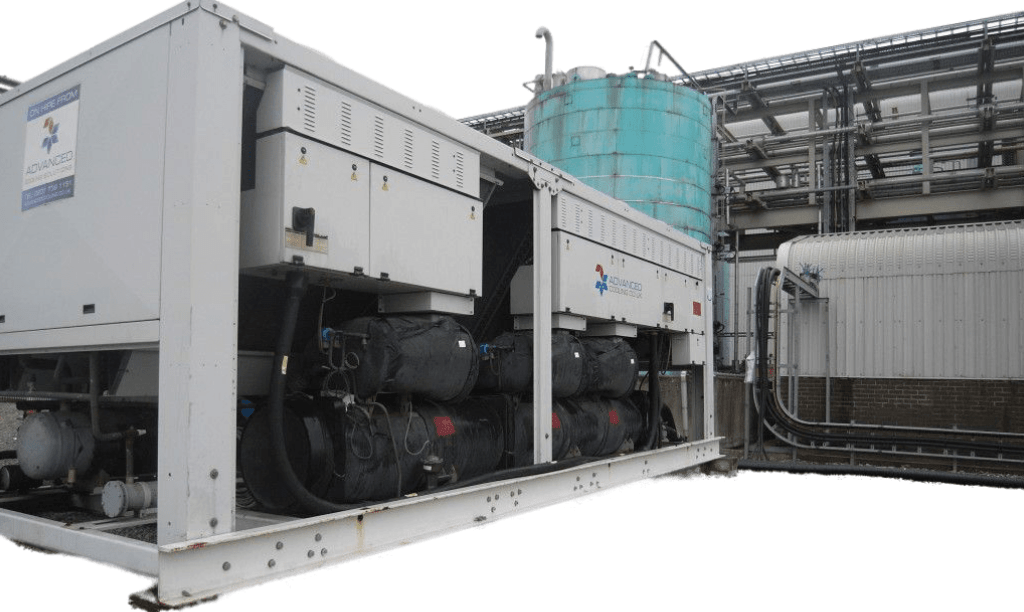

When considering installing a chiller hire system, ‘Full Turnkey’ would generally refer to a complete end to end service from one supplier including the following tasks;

- Surveying site so that accurate proposals are made.

- Designing a suitable chiller hire installation to perform correctly.

- Planning the logistics of delivery and installation labour to site.

- Overseeing the installation process.

- Final commissioning of the installation and hand over to the client.

- Ongoing day to day operation and maintenance of the installation.

🟧 Planned- Including Contingency

Forward planning is a very good idea that can dramatically reduce response times to issues that arise and would involve the following;

- Ongoing day to day inspections of sited equipment to identify and problems or week spots that may require intervention.

- Consider completing a site survey to identify how to quickly facilitate a chiller hire installation.

- Create a written contingency plan that can be referred to in a time critical situation.

- Set-up strong lines of communication with an experienced professional rental company.

🟧 Emergency

In an emergency situation, it is vital that the following steps are carried out in a clear and concise manor to avoid serious consequences;

- Make contact with a reputable chiller hire company- reviews are a good indication as well as word of mouth.

- Collect as much accurate information as possible, including, the type and duty of chiller required, where it will be located, along with any possible connection points for power and water.

- If possible, and if time allows, seek the attendance of the rental companies sales engineer- he will be able to advise on costings and a plan for installation.

There are varying design responses to temporary chiller installations, however the golden rule is to provide a practical and reliable solution that meets the objectives of the different situations presented;

🟧 A Pragmatic Design

The design should not overcomplicate the situation and be a practical solution to the problem without necessarily considering downsides and are generally;

- Fast to install and functional

- Are usually in response to fast moving situations requiring a quick solution.

- Very cost effective because of simple design and installation.

🟧 A Design for Critical Applications.

Creating a design that features resilience at its core should include the following elements;

- Careful selection of equipment that is suited to the process.

- The design should have redundancy built in, for instance, use multiple chillers/ pumps so that there is no single point of failure.

- Use completely separate overlapping systems that will maintain full operation if one or other fails (otherwise known as n+1)

🟧 No Specific Design

Generally, in response to fast moving and/or emergency situations where basic information is available and a dynamic design response is required to as-found site conditions.

- On arrival an experienced installation engineer should survey the situation and present a design, verbally or otherwise, for the installation.

- The solution should be very simple to execute and operate.

- Equipment that can be operated flexibly should be specified to cover all eventualities.

We can help with the following;

- ✅Fast response chiller hire:

- ✅Improving your processes

- ✅Improving uptime and reliability:

- ✅Enhancing Energy Efficiency:

- ✅Planned projects and seasonal activities: