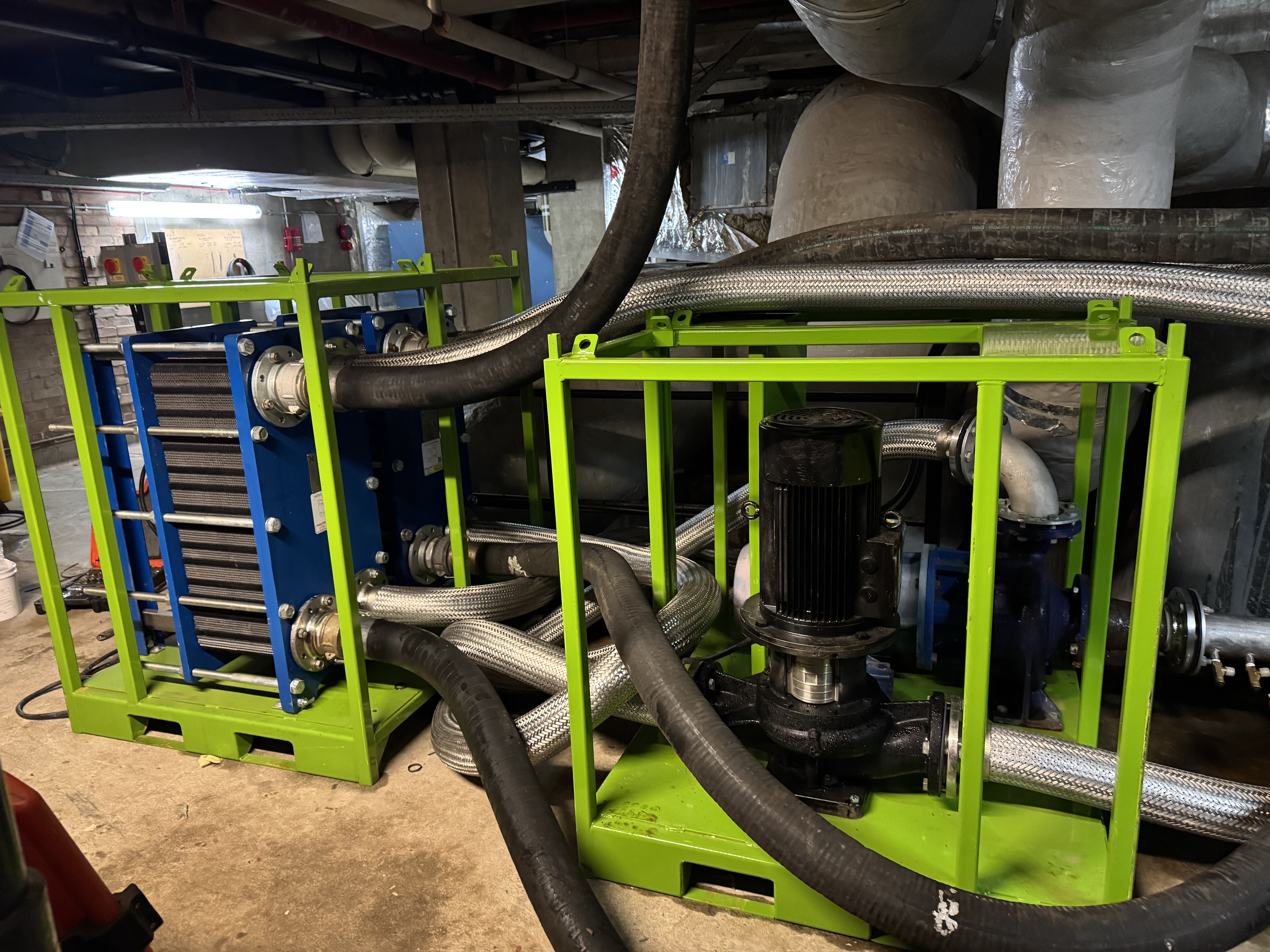

Temporary 1000kw Plate Heat Exchanger Solution

A temporary plate heat exchanger project to maintain building cooling systems during a replacement project.

Briggs and Forrester approached ACR for solution to maintain cooling operations at the prestigious Guild Hall in London whilst the East and West wing chillers were replaced.

These cooling systems are not only required for building air conditioning, but critical for the museum areas where chiller water is used for de-humidification.

The initial strategy was to use temporary water chillers located outside of the building for this purpose- however, due to limited outside space and the long routes for hose and cable into the building another solution was sort.

After much consideration and out of the box thinking, the use of plate heat exchangers was landed-on. The proposed location in the plant room had major advantages over externally fitted chillers, including a massively shorter pipe-work run that would save time and money.

Handily, because of the compact size of the equipment in lifting frames, bringing the equipment into the basement plant room was a straightforward job that was carried out by a specialist lifting company.

But what about the chilled water for the primary cooling at the Plate heat exchangers? This was neatly addressed by re-purposing the condense water pipe-work for the defunct chillers which was connected to the estate chiller system, and in turn to the plate heat exchangers.

Because of the high lift to the roof plant the expected working pressure of the primary system was estimated to be around 5-7bar. In view of this, 15Bar stainless steel braided hose was recommended to ensure safe reliable operation.

Two 11kw pumps were fitted to circulate water to each plate heat exchanger, which in turn independently provided cooling to the East and West block pumps.

This temporary 1000kw plate heat exchanger project was a great success. As with all these projects that come from to some extent the left-field, it was very much a case of refining the installation to meet the clients requirements.

To this end flexibility was designed into the system with oversized heat exchangers and inverter driven pumps.

All in all, commissioning was a fairly straight forward process that involved balancing the flow rates against the temperature of delivery/ return on the secondary circuits.

This temporary system remained in place for a contracted 25 weeks before removal.

A really good job that surpassed expectations.

To find out more about our heavy duty 500kw plate heat exchangers please click here